Hartlepool Sports & Leisure

Hartlepool Sports & Leisure

- Cinemas, Theatres & Dance Halls

- Musicians & Bands

- At the Seaside

- Parks & Gardens

- Caravans & Camping

- Sport

Hartlepool Transport

Hartlepool Transport

- Airfields & Aircraft

- Railways

- Buses & Commercial Vehicles

- Cars & Motorbikes

- The Ferry

- Horse drawn vehicles

A Potted History Of Hartlepool

A Potted History Of Hartlepool

- Unidentified images

- Sources of information

- Archaeology & Ancient History

- Local Government

- Printed Notices & Papers

- Aerial Photographs

- Events, Visitors & VIPs

Hartlepool Trade & Industry

Hartlepool Trade & Industry

- Trade Fairs

- Local businesses

- Iron & Steel

- Shops & Shopping

- Fishing industry

- Farming & Rural Landscape

- Pubs, Clubs & Hotels

Hartlepool Health & Education

Hartlepool Health & Education

- Schools & Colleges

- Hospitals & Workhouses

- Public Health & Utilities

- Ambulance Service

- Police Services

- Fire Services

Hartlepool People

Hartlepool People

Hartlepool Places

Hartlepool Places

Hartlepool at War

Hartlepool at War

Hartlepool Ships & Shipping

Hartlepool Ships & Shipping

South Durham Steel Works

Details about South Durham Steel Works

South Durham Steel Works later British Steel. SEE NOTE BELOW FOR HISTORY

Location

Related items :

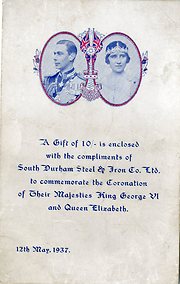

1937 Coronation gift

1937 Coronation gift

Donated by Mrs. Sheila Nicolson

Donated by Mrs. Sheila NicolsonDated 1937

A gift envelope from the South Durham Steel & Iron Co. to commemorate the 1937 Coronation.

More detail » British Steel North Works rear

British Steel North Works rear

Created by Bill Henderson

Donated by Bill Henderson

Created by Bill Henderson

Donated by Bill HendersonDated 1983

Around 1983 when the site was derelict.

More detail » Building the South Works

Building the South Works

Created by NDM

Donated by Hartlepool Museum Service

Created by NDM

Donated by Hartlepool Museum ServiceDated 1958

The South Durham Steel and Iron Company South Works were built on the site of West Hartlepool airport near Greatham. This image shows the building of the works in 1958.

More detail » Coke Ovens, North Works

Coke Ovens, North Works

Donated by Douglas Ferriday

Donated by Douglas FerridayPart of the Library collection collection

Coke ovens at the North Works of the Steel Works.Date unknown although it will be some time ago judging by the attire of the workmen and the lack of health and safety equipment!

HHT&N 843

More detail » Council visit to the Mill

Council visit to the Mill

Created by unknown

Donated by Mr. Billy Henderson

Created by unknown

Donated by Mr. Billy HendersonBilly Henderson and Les Bennett escorting Councillor's on a visit to the South Durham Work's No.4 Mill loading bay, sometime in the late 1970s.

More detail » Demolishing the Steel Works (1)

Demolishing the Steel Works (1)

Created by John Rees

Donated by John Rees

Created by John Rees

Donated by John ReesPart of the John Rees Archive collection

Dated 1975

A view of site clearance at the old South Durham Steel Works in 1975.

More detail » Demolishing the Steel Works (2)

Demolishing the Steel Works (2)

Created by John Rees

Donated by John Rees

Created by John Rees

Donated by John ReesPart of the John Rees Archive collection

Dated 1975

A view of site clearance at the old South Durham Steel Works in 1975, with the extensive railway sidings in the foreground.

More detail » Hartlepool South Works

Hartlepool South Works

Donated by John Anderson

Donated by John AndersonThis photo shows the number 4 blast furnace (tallest structure except for the chimney stacks). To its immediate left are the 3 domed topped hot blast stoves. To the far left is the gas holder. The plume of white steam comes from the coke ovens quenching tower and indicates the oven has recently been pushed and is currently being quenched.

More detail » Memories of Working at the Steel Works from 1933 onwards

Memories of Working at the Steel Works from 1933 onwards

The South Durham Steel & Iron Co.

This is my adult life story in the South Durham Steel & Iron Co.’s employment well over forty years ago. At 16 years old, in 1933, I started work there, and in those days most people were very hard up. Unless you had somebody to put a word in for you, it was a slim chance for anybody to get a job in the steelworks. Even then, the works produced output only three or four days each week. Fortunately, my grandfather had a staff job there and he spoke for me, getting me a start in the works.

Most employees had to work eight hour shifts: 2 pm – 10 pm, 10 pm – 6 am and 6am – 2 pm. My first job was a ‘door boy’. Four hydraulic levers controlled four lifting doors on what was called a ‘side furnace’. A machine called a charger was used to put steel slabs into the furnace. It could swivel round, lift up and down, picking up slabs stacked about 6 foot high, or off the floor. As a rule, two furnaces were used. One end of the furnace blew gas on full for heating slabs practically till they were white hot and dripping with slag, which had to be drained from the back of the furnace. When the slabs were ready, the charger’s massive jaws gripped a slab and deposited it onto the roller gear which carried it to two massive rolls, one above the other, that were driven round by a modified ship’s engine. These rolls reversed as the slab was taken in one side with pressure on it and brought in again with the roller gear with more pressure from the screwing down gear on the slab.

This process went on till eventually it was a long plate rolled down to thickness from an eighth of an inch to a quarter of an inch, or five sixteenths of an inch generally. This was No. 2 mill product, but No. 3 mill had the machinery for heavier plates. My job was to time the doors lifting for the charger to place the slabs, usually four in each partition. By the time the eight slabs in two doors were rolled and replaced, the gas was transferred to the other end of the furnace mechanically. In that time the slabs there were ‘soaked’ to a good red heat and would be heated up easily while the charger started on the other furnace, whose slabs were ready. This was a suitable system of progress in production.

I was paid 2 shillings and eleven pence per shift, in today’s money nearly 15p. my next job was as ‘sparehand’, and as the name suggests I did what I was told to do for 3 shillings and two pence, about 16p in today’s money. I wasn’t tied on the new job and got around the works, which was interesting, seeing different things like the steel plant making the steel, and pouring the molten metal from the steel plant furnaces into massive ladles held by overhead crane. The liquid steel was poured down into them to make ingots.

The ‘cogging’ mill as it was named (I don’t know where the name came from) was a line of below ground to surface furnaces, into which cranes, using scissor-like clamps, lowered the ingots. When heated to a nearly white hot temperature, they were lifted out, as needed, and laid on the cogging roller gear which carried them to massive rolls. These gradually squeezed the ingot, as it passed backwards and forwards, to a slab thickness from 3 inches upwards, say 4,5,6 inches etc. It then passed onto the ‘cogging’ shears which cut off the rough end, then proceeded to the defined length of slab. The slab was then passed on with more roller gear, transferred onto a four wheeled ‘bogey’ and shunted electrically round to No. 2 or No. 3 mill to be charged into their furnaces as needed to be reheated and rolled into plates.

One of my sparehand jobs was to go from the mills to the north side of the steelworks’ footbridge, not far from the Expansion Metal Works, where a large shed contained a scrap cutter machine and railway lines to take trucks in and out. Some of the trucks contained bundles of heather about three feet long. If the bundles were still in the wagon we had to unload it. Usually there were two or three lads and we used to horseplay sometimes, throwing each other into the heather. After that we took a bundle each back to the mills and repeated the procedure until the roller man had enough laid close to the rolls. The slab would be crusted with thick scale, and if this was not removed, the plate would spoil and have to be scrapped. Handfuls of heather thrown on the slab did the trick after a few passes into the rolls.

My job also was to get in stores for the fitters, such as nut and bolts, or to help get the roller gear oiled and greased during the 25 minute meal spell for the mill. One incident during that time involved a young lad oiling the cog wheels during a meal spell. He was a bit late getting off the roller gear, and the controller must have tested the power or something. When the mill whistle that ended the meal spell blew, the cogwheel took down and amputated his leg.

Being a sparehand gave me my first taste of painful injury, and this was followed by many more, much worse, during my span of employment. When all the jobs were done the boss would give us leave to wander around for a while. This particular day, I walked through a boiler house where coal, called duff coal – very small bits and very rich in heat and gas – was wheeled in, in three feet or so high wheelbarrows and fed into the boilers with very long handled shovels. After burning for a while the fuel would cake up, and using a splice – a very long, pointed, steel pole – the boiler man would push and shove to get it blazing again. I know this now, but not back then.

As I walked through I saw the bloke staggering along with his large wheelbarrow and noticed that the splice was across his path. I could see it would take both hands to remove it, and this I did and almost screamed out in pain. The rod as ‘black’ hot as it had just been used. I couldn’t open my fingers after dropping it. My palms and fingers on both hands were burned and the skin was white. The ambulance man had to cut with scissors what apparently were blisters to treat them.

Another time I fancied a smoke and bent down to light a piece of paper for it, on some very hot slag that had spilled from the furnace, when a lad who was carrying on with others couldn’t resist a leapfrog on my back and my hand went flat onto the hot slag. Spitting blue lights is a good caption for that episode!

There was always horseplay and sometimes bullying among the lads. One day I was passing alongside the rolls and roller gear; passing the plate in and out. A big lad, with a ‘big head’ to go with it, was passed me and grabbed me in the groin, which he thought was funny, but which was agonising. I was nearly on my knees. When he released me I brought my fist up – I was only 5’2” and he was 6’ – hitting him with a good straight right on the chin and he staggered and fell on the roller gear. The roller plate engine driver saw what happened and halted the plate two or three feet from him. What might have happened is anyone’s guess. If the plate had kept going it might have chopped him in two, or badly injured him or badly burned him on the plate. When he got up I half expected a punch up as he grabbed me, threatened me and said he’d see me outside at the end of the shift, but strangely enough he just walked past me. After that, when war broke out, he went into the Coldstream Guards. He never troubled me any more.

Later on, I was taken off being a mill sparehand and started training as a sparehand for overhead cranes. These had various uses. I picked up scrap when shears cut it up, putting it into wagons with a magnet. Some had long beams to lift with four or five small magnets on them to pick up plates that were marked out and carried to the shears to be edged off.

The shearmen, about six of them, steered the plates with steel forks on the edges and free turning rolls for support pushed the plate into position for cutting. There were heavier cranes for lifting in or taking the huge rolls out when servicing was required. There were overhead charger cranes for picking up hot or cold slabs as required. There was also a ground charger on lines for another type of side furnace. I got my first crane driving job on a small crane in the Sheet Mills, so called because it rolled very thin sheets of steel from heated pieces of steel generally about 12” to 14” wide, 30” long and half to one inch thick. Naturally they were rolled with a smaller type of rollers. These were driven round one way all the time, propelled by a massive wheel driven by steam, which must have been about 30’ in diameter.

I think the roller men team constituted four men. On each side pulled a bent-over lever from the top of the screwing down mechanism, and had to be matched evenly when the hot plate was pushed into rolls manually. These pushers had long-handled tongs and were called heaver-overs. Good team work was required from each side. The white hot piece of seel was first pushed in one side, then picked with tongs on the other side. The knack was to lay it against the roll, and as it was going one way it helped to carry the steel plate over the top where the chap on the other side would catch it with his tongs and down it so he could push into the rolls again, as the screwing down lads put a bit more screw on it. It was a fascinating skill to watch, and as the plate got longer, the heaver-overs sometimes had to slide backwards holding the plate and get the opposite end of the plate into the rolls. The men adjusting the screwing down machinery were called breaker-downs, I don’t know why, and they decided when the gauge was reached.

Nearly all the men in that mill wore clogs, with high leather ankles, very thick and the soles and heels edged with steel strips, looking similar to the horseshoe idea. The reason for this was that most of the floor was steel-plated and the finished sheet metal was laid about in different piles – the clogs provided insulation from the heat. When the sheets were cooled off, they were dragged with tongs to the shears, marked off and cut, put in neat piles and then, when thick hawser wires were looped round each end, the O.H. crane picked them up and transferred them ready for loading into wagons, when firm and destination had been checked.

Some of the men walked to work in clogs and people in the area of Oxford Road would often hear the clang, clang of them when workmen going for the 6 am shift passed. The people in the area also had to put up with load clanging when steel was being passed into the sheet mill rolls.

Working conditions weren’t very good. When the wind blew in the wrong direct, that is into the mills, the dense black smoke billowed down from the larhge chimney near the steelworks offices near the bridge, causing choking fumes, and, of course, there were plenty more smaller chimneys about the works. Most workmen went home as black as crows, showing the white of their eyes.

I worked on a 4 or 5 small magnets overhead crane next, picking up finished plates from No. 2 mill, laying them in a line of about twenty, working end to end. The marker chalked his measurement when the plates were cool enough, then I transferred them to the shears to be cut. It was a continuous process and generally the only spell I got was a breakdown or my meal spell.

The driving cabin was open all round and was on the seaside end. At times, in winter, the snow blew in all around me and Id wrap up in my overcoat, cap covered with a scarf and knotted round my neck, and sacks tied with string round my legs. After that job I moved to No. 2 mill maintenance crane, working for fitters and millwrights in repairing roller gear and changing the big rolls. Weekends were the busiest times.

I remember once Sunday morning when it was very cold after it had been snowing. During a break while waiting for maintenance to arrive, I was keeping warm near a furnace with a lot more men. The rolling gear etc., was in front, and a fitter and his mate were repairing the screwing down gear. The fitter’s mate, about 20 years old, was sitting on the top, tightening up the bearings. When they finished they had to run the machinery to check it. For some reason this happened before the lad got down. He spun round the shaft like a rag doll, bits flying off his body. The mistake was remedied in seconds, but too late for the poor lad. He just hung by his torn clothes. Everybody was petrified. I called for some help to do something but no-one moved. His mate walked away from the scene and as he passed me he said, “for God’s sake somebody do something!” I couldn’t believe it! I was trembling myself with horror, but something had to be done. I walked to the poor lad and he just stared at me, his eyes rolling. Anyone could see he was dying. I shouted for somebody to help me, but nobody moved. I got hold of him with my arm around his waist, the other under his legs, but he was just slipping away with all the blood covering his bare body.

Everybody just watched me. I felt sick. Then a chap who was pally with me came out of his cabin a good way away, saw me and hurried over. He helped me sit the poor fellow on top of the big roll and borrowed my pocket knife to cut the clothing so we could lift him down on to the cold steel floor, just as an ambulance man arrived with a stretcher.

I had some traumatic nightmares for a while after that. I couldn’t understand why all those men just watched without lifting a finger.

My next job was driving the No. 2 mill charger, feeding the mill with slabs for rolling. During that time the 1939 war broke out. The whole steelworks had emergency light warning day and night. A yellow light was for standby, that enemy aircraft were approaching; if the red light appeared, lights everywhere were blacked out with sirens blaring. We had to seek cover in the air-raid shelters provided at convenient points, which was a bit tricky in darkness with all the obstruction about the place.

One hair-raising experience I had was when a surprise German plane beat the air-raid scanners one night and the lights went out suddenly, accompanied by sirens. Everybody ran for it, but I couldn’t – I was unloading a bogey load of very hot slabs and the glow was stark against the darkness, showing very vividly to the sky. I could hear the plane and anti-aircraft guns in action, with searchlights probing about. My foreman came running over and pressed me to unload the slabs and put them anywhere under cover in the mill’s building. He and some other workers threw corrugated sheets and anything of that nature over the top of the slabs, also shovelled sand and scale on the slabs. I had to be guided with a torch where to place them. Anyway, the emergency blew over safely without anybody being blown up!

Some bombs did drop, about 7 or so just outside No. 2 mill near a boiler and gas main. Later in the war, the boiler man got killed, the gas pipe ignited causing problems. Another bomb hit the store house not far away, didn’t explode. Bomb disposal engineers defused it after digging down for it, as calmly as you like.

My next job was in the new No. 1 Mill, driving a ground charger that ran on lines in front of the side furnaces which heated slabs for the mill. Alongside was a push furnace, so called because it pushed slabs in one end, and, as it did so, a slab slipped down a ramp at the other end, being heated up by the time it dropped down. The side furnace was used to relieve the push furnace if heating wasn’t up to scratch, or something had broken down.

It was still war time. Some of the steelworkers were called up for the forces, so women were drafted in to drive electric cranes sweep up, and one or two other jobs they could handle. I missed the call up because I received a card from the ministry advising me I was in a reserved occupation, classed as semi-skilled.

I volunteered for the Territorial Army thinking I might be able to get to the action in the war as some Terriers had been drafted in to support the army. “Get back to work!” i was told. The same applied even for the Civil Defence.

Anyway, the Local Defence Volunteers were formed, giving a bit of satisfaction’ these were later nicknamed Look-Duck-Vanish! If German paratroops had dropped in after L.D.V. had just started to be organised, there might have been some truth in it! Different parts of the town had their own units and headquarters, such as the South Durham Steelworks, the shipyards and other organisations.

My first weapons were a pick-axe handle and a sporting shotgun. At the time, “look-duck-vanish” could have been a reality if we’d been attacked! After a good while the Home Guard, or ‘Dad’s Army’ was formed.

While the war was on every steelworker had to cover his job. If his mate on the next shift took ill, or failed to arrive, he had to work on and do a double shift or hope his foreman could get someone to take over. That was a strict wartime stipulation; production had to be kept going for the war effort.

Being a Home Guard, outside of our working hours was another chore. We had to go on parade on Sundays, do training for using weapons as new types came, such as machine guns, tommy guns, mortars, sten guns, mills bombs, anti-tank bombing and also gas mask drill. Ive known us march from the steelworks across to West View and back.

When using bombs we went to the ‘Snooks’, where the Greatham Creek area was, or the ‘Blue Lagoon’and ‘Slag Wall’. With Mills Bombs there was a target. When your turn came a live bomb was thrust into your hand, then you had to run towards some sand bags. On reaching them, you pulled out the pin, threw the bomb at the target, then dropped behind the sand bags for shrapnel protection on exploding.

On one occasion, I was told that a chap took fright and ‘froze’ when he threw the bomb and it dropped very close. Sergeant Walter Nunn, in charge, ran and pushed the fellow down, and both were injured from shrapnel. Being on the ground saved them from serious injury. I think the Sarge was the first Home Guard recipient in the country to get a wound stripe.

At times we were enlisted to night patrols; sometimes for fire watch in case of bomb attacks from ‘Gerrys’, sometimes we would go to patrol headquarters to report for duty at the Marine Hotel, at Seaton Carew. We’d set off and walk right along Port Clarence Road to the junction of Brenda Road, then back to Seaton Carew. It was a precaution I suppose, for anything suspicious happening. Of course we were armed – some with Sten guns, others with rifles – and in contact with headquarters.

Another story I was told concerned an incident in the Marine Hotel, when a patrol reported in there. One of the men slipped a Sten gun from his holders and bumped it, butt first; being spring-loaded this bounced the firing pin and fired a bullet through the ceiling, causing uproar in the bedrooms, and one or two screams. Apologies all round I suppose.

These duties had to be done, even though we might have worked a double or twelve-hour shift. There’d have to be very mitigating circumstances to avoid doing these duties.

During this time I left No. 2 Mill to drive the ground charger on the side furnace in the new Mill adjacent to Mainsforth Terrace and steelworks footbridge. In line with the side furnace was a push furnace. Slabs were pushed in one end, going through a fierce heating process, and sliding down a ramp at the other end as needed onto roller gear that carried them to the big rolls to be made into long plates. The side furnace’s role was to relieve the push furnace and keep a constantly good heating for the slabs as necessary.

Funnily enough, my job driving the charger was very cold in the winter, being wide open to the elements because of rail traffic for the mills requirements. Although I was in close to the furnace, to withdraw and charge slabs, I was well wrapped up to keep warm. In theory, where hot air rises, cold air is drawn in. On hot summer days I was drenched with sweat and often worked with just a shirt on, pulled out of my trousers. Then I got a side furnaceman’s job, learning the ins and outs through “being on the job” as the saying goes.

Mixing gas and air for a good heat was the aim, together with seeing that everything was working correctly. If not, I had to correct it, as an explosion in the furnace could cause mayhem, perhaps injury. Talking about injury, I felt I was accident-prone on that job. When the ground charger put a slab on the roller gear to be made into a plate, my duty as a furnaceman was to ensure the slab reached the big rolls. Now and again the slab would twist and jam, corner to corner, on the sides of the roller gear. Taking a long bar, I had to prise it straighter so it would carry on its journey.

In one incident it was jammed and wouldn’t budge no matter how I levered it. My charger driver tried to help by forcing the bar upwards under the slab, but the weight was too much and the bar came down, hitting my head forcefully on one side. I was partially stunned and with some help got off the roller gear and just sat on the floor with blood running down my face and chest. An ambulance took me to hospital for observation for a while, then put half a dozen stitches in the wound and sent me home to a wife who was perturbed at seeing me helped out of an ambulance with a blood-stained shirt and face, and still shaken.

Next was a serious accident, barring a slab along the roller gear again, as it had stuck in front of the push furnace doors that lift up and outwards as the slabs are pushed, then slide down a ramp onto the roller gear. A platform above made it dark, and I didn’t see that one or two foot plates between the roller gear were missing and whilst prising the slab I dropped down one of the gaps. Only one of my arms saved me from dropping about ten feet or so below, and they were badly burned off the hot roller gear. My ribs were broken at the back. The woman at the rear end of the push furnace thought the mill was waiting for a slab, because there was no action in rolling a slab. So she started the process of lifting the doors to push a slab out. The woman at the front end signalled with a push button light flashing on and off to stop action from the other end, and screamed with terror at my predicament. Anyway, the pushing stopped.

Ive heard about looking into the jaws of death and I couldn’t have had a better demonstration. White hot scale slid around me from down the ramp as I saw the heated slab slowly moving. Another two seconds and I’d have been a goner, but fortunately, the doors closed. My poor wife was subjected to another ordeal, going to the hospital and, as we had a little boy, it spoiled our Christmas, which was just a week away.

Time passed by being a furnaceman until up to 1960 or more. Then, one day after looking into the furnace to satisfy myself that the heat of the slabs might be ready for rolling. I went back to the door levers to drop the doors, when the overhead charger passed over and I didn’t get a warning from the driver with the bell he should have used to alert me. He was dragging two slabs in scissor type ‘dogs’ over other stacks of slabs when the bottom slab of the two slipped out of the ‘dogs’ with the bumping. I just heard the noise and didn’t see it, realising afterwards that’s what happened. My back was towards it and as it dropped, the end of it struck my shoulder blade, luckily, you might say, because I was flung forward and the slab hit my left foot, mainly the heel, and slid a foot away from me because the ground was quite soft. At first, the nbumbness in my leg gave the impression it was off and it seemed an eternity before somebody realised I needed help. Another ambulance trip to hospital, but I didn’t get home until four months later.

After three operations – one through infection, another sorting the small bones and clearing the broken ones, plus skin grafts after that – eighteen months off work with £7 10 shillings a week to live on was hard going. The nastiest thing was my employer’s attitude when I wanted to return to work. I was crippled for life and finding a suitable job with them wasn’t easy. So when the employment manager said the firm had no obligation to give me a job after thirty years’ service, it knocked me for six. If I wanted to drive any mechanical machine again, I couldn’t do it if there were ladders to climb, and most cranes and chargers had those.

No. 1 Mill was being closed down at that time. Fortunately, a workmate of mine, who started the same day as me and with whom I’d been good pals since, met me when I was applying for work in the firm’s employment department. He’d done well there at the works and was foreman in the overhead cranes department for the new steel plant that had opened up. He was very sympathetic to my predicament and promised me a suitable job if he could in the future. Lo and behold it came off. He sent for me and showed me the job. It was a charger again, feeding the furnace with scrap steel, iron ore and lime. To drive it, I stepped from floor level to occupy the seat and manipulate the controls, which hoisted the platform about six feet or so high, to transfer pans about seven or eight feet long and two feet wide into the furnace, where the pan was turned over, dropping the contents into the furnace.

It was good to be back after eighteen months out of work, although my accident-prone jinx still dogged me. After the furnace discharged its molten metal into massive ladles, it had to be recharged, starting with lime and ore already filled up in pans, four in a tray, seven trays lined along a bench. First the lime was spread along the bottom of the furnace, which helped to thicken any liquid metal that was surplus. Then the ore, because if dropped into molten metal it erupted, for all the world like the pictures on films of boiling lava from volcanoes, only on a smaller scale. The dangers were obvious.

Charging the furnace would be plain sailing for, say, 90% of the time, but the ore, lime and scrap were brought in by railway transport from outside and sometimes snow, or heavy rain, saturated the pans. If left outside long enough the top would dry off, giving the charger driver, the impression that the pans were dry. Lime, if wet or damp would blow up a bit, causing billowing dust from the furnace and the driver would have to duck to protect his face. Ore, once dropped in the furnace wet or damp, caused a flurry of flames gushing upwards and outwards towards the driver who, sensing the danger, would retreat out of the furnace as quickly as possible, because there would be an explosion, either big or small. The only protection was a four foot square of fireproof glass, which used to shatter into small pieces if blasted hard or hit with bits from the blast.

When the furnace started to reach a very high temperature and bubbled it was very tricky. The furnaceman took samples from very long-handled steel rods with a three inch cup on the end. When cooled, the sample was taken to the laboratory and analysed. The result was given through a tannoy, like a loud microphone and the head furnaceman would decide if the result was good enough to tap the molten steel into the massive ladles at the back.

It the result was unsatisfactory he would order the charger driver to put in either some lime or some ore. If lime was used there was little danger, but ore had to be trickled out of the pan with pauses in between because of the blow out of flames. But accident prone me had the awful experience when sprinkling ore in the funace, of my electric control jamming during the tip-over procedure. All the ore just tipped out pretty quickly. A great roar from the flames blowing out made me slam the cross travel controller to back pedal out, and I threw myself to the floor. I had burns to my face and my clothing was singed. The charger was in flames from top to bottom. With the wiring burning, the hoist which lowers the platform on which I sat was immobilised. The heat was unbearable, and though disabld I had to take a chance and jump down to safety, relying on my good leg to break the fall, which it did in a ‘hopping’ sort of way. Seeing the charger in flames was an enthralling sight, at about forty feet high. No ambulance this time – just burns to my face and arms which were secondary.

One charge driver experienced nasty burns when a pan of scrap he was charging had a small butane gas bottle buried amongst it. Being unaware of its presence, he took the blast of it coming out of the furnace – it was like a bomb going off. I once put a deceiving pan of lime in the furnace that was wet underneath; fortunately, the heat was low, but it gave a bang and darkened the plant with dust. Workmen came running up to see what had happened – all they saw was me getting off the charger with the whites of my eyes distinctive like a Black and White Minstrel.

Accident-prone for the last time in the steelworks; I’d set off from work for home along a transit road on my moped when it skidded on a concealed railway line under a lot of dirt. I dived off with arms outstretched, dislocating my shoulder. Another ambulance !

There were a lot of deaths during the time I worked at the steel plant. Some bricklayers died from injuries received when a furnace caved in whilst under repair; another chap was run down and killed with a fork lift; and a fellow was knocked off the edge and into the bottom of a ladle that hadn’t long been emptied and died from his burns. There was a young fellow who fell from the top of the plant roof on New Year’s morning; nobody knew why he was up there, but he died instantaneously.

That was the last New Year for the steel plant. Within the next three months it was closed down and everybody made redundant. I was in my sixties and best of all, the accident-prone jinx wouldn’t be breathing over my shoulder. There were some accidents I haven’t mentioned.

Besides that, I was a misfit amongst most of my colleagues being a non-drinker and non-smoker, but I got along with them all right generally. I’m sure all the time dust, etc., that I breathed in is the cause of my being a bit ‘chesty’, like a lot of other steelworkers. I think it left us scarred in that sense. Over all those years in service I couldn’t help feeling resentful at working there, but it was a living and supported my family. I think it was the hard times in the nineteen-twenties that gave me the resolution to plod on.

More detail » Pipe bridge - Brenda Road

Pipe bridge - Brenda Road

Donated by Hartlepool Library Service

Donated by Hartlepool Library ServiceSteelworks use the gases from the blast furnaces and coke ovens as fuel in boilers and reheating furnaces. With the opening of the SDSI South Works, it was necessary to connect the gas distribution system to that at the North Works, and this bridge carried the connecting pipes over Brenda Road. It also carried the rail link between the works.

More detail » Quote for Steam Driven Overhead Crane

Quote for Steam Driven Overhead Crane

Donated by Keith Alder

Donated by Keith AlderPicture of a steam driven overhead crane- this gives an idea of what the crane looked like.

More detail » Quote for Steam Driven Overhead Crane

Quote for Steam Driven Overhead Crane

Donated by Keith Alder

Donated by Keith AlderNotes on West Hartlepool Steel and Iron works- August 1893

More detail » Quote for Steam Driven Overhead Crane

Quote for Steam Driven Overhead Crane

The West Hartlepool Steel & Iron Works were formed in 1881 after taking over part of the former Iron Works & Rolling Mills of Thomas Richardson (The West Hartlepool Iron Company)

Part of the Iron Works was extended and modified to produce steel using Siemens Marten Open Hearth Furnaces . As part of this new installation, an Overhead Travelling Crane was necessary, This would have run on iron rails mounted on horizontal beams and supported on vertical columns. The crane covered part of the steel plant-The Casting Bay, where the steel would be cast into ingot moulds,- The Cogging Mill, where the steel ingots would be rolled into slabs, fnally, No.3 Mill, where slabs would then be rolled onto steel plates.

This crane would be used for fitting ingots, rolls and other heavy items. It would have been powered by steam from a boiler and a steam engine mounted on a crane.

Joseph Booth, crane manufacturers in Leeds, quoted for the manufacture, supply and erection of a Steam Driven Overhead Crane in the New Steel Works constructed in 1883.

The West Hartlepool Steel & Iron Company was the pre curser to The South Durham Steel Corporation formed in 1967.

More detail » Railway Lines, Steelworks

Railway Lines, Steelworks

Created by NDM

Donated by Hartlepool Museum Service

Created by NDM

Donated by Hartlepool Museum ServiceThere are at least 14 sets of railway lines on this photo of the North Works in the early 1950s. Today there is one north and one soutbound line in the same place.

Amongst other things, the trucks are carrying steel, coal and pit props.

More detail » South Durham Steel Works (4)

South Durham Steel Works (4)

Donated by Hartlepool Library Service

Donated by Hartlepool Library ServiceSouth Durham Steel Works.

More detail » South Durham Steel Works (5)

South Durham Steel Works (5)

Donated by Hartlepool Library Service

Donated by Hartlepool Library ServiceSouth Durham Steel Works.

More detail » South Works

South Works

Donated by Douglas Ferriday

Donated by Douglas FerridayPart of the Hartlepool Library Service collection

Dated 1965

Taken in 1950s, the image shows the South Works of South Durham Steel and Iron which had opened in 1958.

HHT&N 125

More detail » Steel shunting

Steel shunting

Donated by Douglas Ferriday

Donated by Douglas FerridayPart of the Hartlepool Library Service collection

A small shunting engine at the South Durham Steel Works in 1946.

More detail » Steel works 1919

Steel works 1919

Donated by Jacky Armstrong

Donated by Jacky ArmstrongDated 1919

A group of steel workers - Thomas Henry Wood is second from the right.

More detail » Steel works bridge - 1975

Steel works bridge - 1975

Created by John Rees

Donated by John Rees

Created by John Rees

Donated by John ReesDated 1975

The well-known Steel works bridge, which crossed the railway lines from a point behind the Expanded Metal works to the Seaton side. It has now been replaced with a small wooden bridge.

More detail » Timeline history of West Hartlepool Steelworks

Timeline history of West Hartlepool Steelworks

Brief History of Steel Working in Hartlepool

Circa 1847 Thomas Richardson set up the Hartlepool Iron Works.

Circa 1855 John Pile opened the West Hartlepool Rolling Mills and built blast furnaces to supply plate for his shipyard.

1867 Liquidation of Pile, Spence and Co and the West Hartlepool Rolling Mills were idle for some time.

Circa 1868 The Hartlepools’ first Parliamentary election won by Ralph Ward Jackson who defeated Thomas Richardson, son of Thomas, the late owner of the Hartlepool Iron Works. Thomas Jnr. Bought the West Hartlepool Rolling Mills for £21,677.3s.0d and extended them. He increased the workforce from 500 to 2,500.

1874 Thomas Richardson Jnr. extended the site. The Mills were extended from 6 to 12 acres and 3 new blast furnaces covered 20 more acres.

Richardson bought the Longhill Estate of 150 acres close to his works and it was here that most of his workforce lived. The area was iosolated with no drainage, sanitation or lighting and became known as Wagga.

1880 Thomas Richardson ran into difficulties and in 1881, Matthew Gray, son of shipbuilder William Gray and Arthur Gladstone took over the works and they became West Hartlepool Steel and Iron Company.

1881 Seaton Carew Iron Company formed.

1896 Matthew Gray died, Mr Gladstone having retired in 1891 and the West Hartlepool Steel and Iron Co. blast furnaces were taken over by the Seaton Carew Iron Company.

Meanwhile, Christopher Furness who ran the Furness Shipping Line amalgamated with Edward Withy and from 1891, Furness Withy was building and running its own ships. Furness recognised that if he owned the steel works too, he would not need to buy steel to build his ships.

1898, Furness bought Stockto Malleable, Moor Steel and Iron Works and the West Hartlepool Steel and Iron Company. This amalgamated group became known as South Durham Steel and Iron Company.

1902-4 brought a recession and plate manufacture was concentrated on the South Durham Works, materials being supplied by Cargo Fleet Iron Company.

1912 Christopher Furness died and the 1st War followed.

1913 Steelworks Footbridge linking Oxford Street/Greatham Street through the heart of the North Works and railway lines to Seaton seafront.

1928 South Durham Steel and Iron Company acquired Seaton Carew Iron Company. The West Hartlepool works then covered 303 acres.

1945 After the 2nd War , it was decided that plate production be increased in West Hartlepool and a new site was planned.

1951 Steel was nationalised under the Iron and Steel Act and South Durham Works became part of the Iron and Steel Corporation of Great Britain.1961 The South Works as they were known were opened on land between Greatham and Seaton which had been West Hartlepool Airport.

1967 North and South Works became part of British Steel.

1971 Last plate at no. 1 Light Plate Mill

1975 North Works slag banks removed

1977 North Works completely demolished

1977 1500 Steel jobs lost in the town. Last steel produced in Hartlepool

1978 Cooling towers demolished

1990 Last cooling tower of South Works demolished.

1999 British Steel taken over by Anglo Dutch Corus

2007 Corus became Indian owned Tata Steel. Only pipe making left at Hartlepool and currently an uncertain future.

More detail » War Memorial Steelworks Club

War Memorial Steelworks Club

Part of the Hartlepool Museum Service collection

Part of the Hartlepool Museum Service collectionTaken in the grounds of the SteelWorks'Club in Westbourne Road

More detail » War Memorial, Steelworks Club

War Memorial, Steelworks Club

Donated by Hartlepool Library Service

Donated by Hartlepool Library ServicePart of the Library collection collection

In the grounds of the Steelworks Club in Westbourne Road is a war memorial to commemorate the deaths of local steelworkers in the world wars.

More detail »